The following terms relate to the installation and use of Vitrified Clay Pipe. Many of these terms are used in reference to all pipe installations while some are specific to VCP installations. Most of these terms can be found in ASTM C896 Standard Terminology Relating to Clay Products.

A

Angular Material

A fractured and suitably sized bedding for pipe and fittings.

Approving Authority

The individual official, board, department, or agency established and authorized by a state, county, city, or other political subdivision, created by law to administer, and enforce specified requirements.

ASTM Standard

Manufacturing, installation, and testing standards issued by the American Society for Testing and Materials.

B

Backfill

All the material used to fill the trench from top of bedding to finished surface.

Backfill, initial

Material used to fill the trench from top of bedding to a designated height over the pipe.

Backfill, unconsolidated

Non-compacted material in place in the trench.

Barrel

The cylindrical portion of a vitrified clay pipe exclusive of branches, spurs, joints, and handling rings or lugs.

Bearing Strength

The non-destructive limit of pipe load, as determined by 3-edge bearing test method, used to determine field supporting strength.

Bedding

The materials, their placement, consolidation, and configuration, as designed to support and to develop field supporting strength of vitrified clay pipe.

Bedding Material

Material placed under and around clay pipe to develop the required load factor.

Bell

The flared-end portion of a vitrified clay pipe or fitting, designed to function in the joining of other such pipe.

Blister

A convex, raised area on the pipe surface indicating an internal separation.

Body

C

Chip

A small piece of broken-off material, or the location where a small piece of the unit material has been broken off.

Clay

An earthy or stony mineral aggregate consisting essentially of hydrous silicates of alumina, plastic when sufficiently pulverized and wetted, rigid when dry, and vitreous when fired to a sufficiently high temperature.

Closure

See compression joint.

Compaction

Densification of soil by means of mechanical manipulation. (Per ASTM D653)

Compression Coupling

See compression joint.

Compression Disk

A disk of compressible material placed between the ends of adjacent pipe for the purpose of distributing the jacking force.

Compression Joint

A joint designed so that a sealing action is obtained by compressing elastomeric components.

Conduit

A pipe for conveying fluid.

Consolidation

The gradual reduction in volume of soil over time.

Controlled Low Strength Material (CLSM)

Flowable low compressive strength cementitious material used in the pipe zone as a bedding material. Also referred to as controlled density fill, flowable fill, slurry, or lean concrete.

Coupling

A device, typically made of an elastomer, used to connect clay pipe barrels. These devices are typically used in conjunction with stainless steel tightening bands.

D

Deadload

The load imposed on pipe that is determined by depth and width of the trench at top of pipe, as well as unit weight and character of backfill material.

Density

A value in lbs. per cubic foot of volume for a given material.

Design Trench Width

Trench width at the level of the top of the pipe.

Drains

A piping system used to collect and carry off surface and ground water.

E

Encasement

Special materials, their placement and configuration which are designed to fully surround the pipe and develop a field supporting strength which exceeds that developed by other commonly used installation and bedding techniques.

F

Final Backfill

Material used to fill the trench from the top of the initial backfill to the finished ground surface.

Fitting

Products such as wyes, tees, elbows, adapters, etc. used in the installation of vitrified clay pipelines.

Flooding

A means of compacting trench backfill by the introduction of water by gravity.

Foundation

The native or prepared trench bottom on which the bedding is placed.

Fracture

That portion of a vitrified clay pipe from which a fragment has been broken. It is distinguished by well-define fracture faces and sharp edges where the fracture faces meet the surface of the pipe.

G

Geotextile

A drainage fabric which allows the flow of water while preventing the movement of soil.

H

Haunch

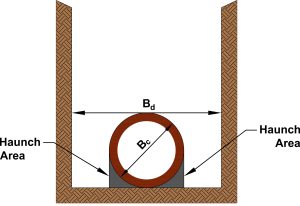

The areas bordered by the barrel outside diameter, the vertical tangents from the pipe springline and the horizontal tangents from the bottom of the pipe. See detail:

Haunching

Utilizing a shovel, spade, or other suitable tool to place and compact the bedding material in the haunch to (1) assure the pipe will remain true to line and grade and (2) provide uniform circumferential support to the pipe which is essential for the total load factor to be realized.

I

Inch-Pound Units

The units of length, area, volume, weight, and temperature in common use in the United States. These include but are not limited to: (1) length-feet, inches, and fractional inches, (2) area- square feet and square inches, (3) volume-cubic feet, cubic inches, gallons, and ounces, (4) weight-pounds and ounces, and (5) temperature-degrees Fahrenheit.

Industrial Waste

The water-conveyed residues resulting from manufacturing or processing operations.

Infiltration

The quantity of ground water entering the pipeline in the test section during a specified time period.

Initial Backfill

Location for placement of selected material, native or import, extending from the top of the bedding material to an elevation 1ft. above top of pipe.

J

Jacking

A method of installing pipe by the trenchless method using equipment and pipe designed for this purpose.

Jacking Force

The force applied to the pipe along the longitudinal axis of the pipeline by the pipe jacking equipment.

Jacking Frame

A structural component that houses the hydraulic cylinders used to propel the tunnel equipment and pipeline. The jacking frame serves to distribute the axial thrust load to the pipeline and the reaction to the shaft wall or thrust wall.

Jacking or Launch Shaft or Pit

Excavation from which trenchless technology equipment is launched for the installation or renewal of a pipeline.

Jetting

A means of compacting trench backfill by the introduction of water under pressure through a nozzle.

Joint

An individual length of pipe, or the means of closure to form a pipeline.

L

Laser

A device that sends a straight beam of light on the proper line and grade to a target.

Leachate

Liquid drainage normally associated with contaminated soils and solid waste landfills.

Live Load

The portion of the load transmitted to pipe from wheel or tread impacts.

Load Factor

The multiplier associated with class of bedding used to compute the field supporting strength (FSS). FSS = (minimum 3-edge bearing strength of pipe) X (Bedding Class Load Factor)

Lot

Specific group of clay pipe having characteristics of sufficient similarity that individual specimens selected from that group may be considered representative of the whole group.

M

Migration

The movement of soil into adjacent material.

Mitered Fittings

Fittings manufactured by using mitered pipe segments.

Mitered Pipe

A pipe with an end angled to mate with a complimentary pipe end or adjust to another surface.

N

Native Material

Material present in or which has been removed from the trench.

Nominal Diameter

References the internal diameter in name only to the nearest unit dimension.

Nozzle

A device designed to control the direction or characteristics of a fluid flow (especially to increase velocity) as it exits or enters and enclosed chamber or pipe. Nozzles can be static or rotational.

O

OSHA

Occupational Safety and Health Administration.

P

Pilot Tube Guided Boring Method (PTGBM)

Also known as Pilot Tune Method (PTM), Pilot Tube Microtunneling (PTMT), Guided Boring Method (GBM), and Guided Auger Boring (GAB). This technique is a multistage method of accurately installing a product pipe by use of a guided pilot tube which is followed by upsizing to install the product pipe. In PTGBM, the guidance system consists of a LED target housed in the steering head, digital theodolite with camera and a monitor screen.

Pipe

See vitrified clay pipe.

Pipe Bursting

Process by which existing pipelines are broken by mechanical fracturing from either inside or outside with the remains being pushed into the surrounding soil while simultaneously inserting a new pipeline of equal or larger diameter.

Pipeline

Pipes joined to provide a conduit through which fluids flow.

R

Reach

The section of a sewer between structures.

Reception Shaft or Pit

Excavation into which trenchless technology equipment is driven and recovered following the installation of the product pipe.

Riser

Building sewers connected to deeper main lines.

S

Sample

Each pipe or group of pipe selected from a lot and used to determine whether the product complies with the specification criteria.

Sampling

Process of selecting samples from a lot for use in testing.

Sealing Element

A separate or bonded material between the sleeve and the pipe that forms a seal.

Segmental Testing

A method of isolating and testing portions of an installed pipeline to determine the location of an air loss in excess of the standard.

Sewage

Waste matter carried off by sewers.

Sewer

Generally, an underground conduit usually carrying waste matter in a liquid medium.

Sewer line

See sewer.

Sewer Pipe

Vitrified clay pipe as described in ASTM Specification C700.

Sewerage

System for collection, treatment, and disposal of sewage.

Shale

A thinly stratified, consolidated, sedimentary clay with well-marked cleavage parallel to the bedding.

Sheeting

Wood or metal restraints used to support the trench walls.

Shield

Movable trench box used in place of sheeting and shoring.

Shoring

Equipment used to prop or support the trench sheeting or trench wall directly.

Shovel Slicing

Utilizing a shovel, spade, or other suitable tool to place and consolidate the bedding material in the haunch to assure the pipe will remain true to line and grade and provide uniform circumferential support to the pipe which is essential for the total load factor to be realized.

Sleeve

A coupling which contains or compresses the sealing element and meets the requirements of the standard. The sleeve may be affixed to one end of the pipe at the factory.

Sliplining

A method of inserting new pipe into an existing pipeline.

Slurry Microtunneling

Trenchless installation of pipe by jacking the pipe behind a remotely controlled, steerable, laser guided, microtunnel boring machine that provides continuous support to the excavated face under various geotechnical conditions including the presence of groundwater.

Socket

The portion of a jointing system that is designed to accept a plain-end pipe or a spigot-end pipe.

Specifying Agency

The individual engineer, firm, or political subdivision charged with and having the responsibility for the design of a facility, product, equipment, or material requirements.

Specimen

Sample, or portion thereof, which is to be tested and the test results to be reported.

Spigot

That portion of a vitrified clay pipe that fits into the bell or coupling of the preceding pipe.

Spring Line

The line of maximum horizontal dimension of the transverse cross section.

Steering Head

In pilot tube method, a rotatable slant faced unit located directly in front of the lead pilot tube that can be adjusted to steer the bore.

Stopper

A plug inserted in a pipe or fitting.

Superimposed Load

Load imposed by travel over, or by material brought and placed over the trench area, after pipe installation.

T

Tapping

A method used to field connect a building sewer to a main line.

Test Section

The portion of pipeline under test.

Test Specimen

Specimen, or portion thereof, which is to be tested and the test results reported, or which is to be prepared for further testing, and the test results reported.

Theodolite

An instrument for measuring both horizontal and vertical angles.

Thrust Ring

A fabricated ring that is mounted to the face of the jacking frame. It is intended to transfer the jacking load from the jacking frame to the thrust bearing area of the pipe section being jacked.

Transition width

The trench width, measured at the top of the pipe barrel, where backfill loads reach a maximum and are equal to embankment load. Further widening beyond this width will not affect the backfill load.

Trenchless Technology

(As defined by the North American Society for Trenchless Technology)

A family of construction techniques for installing or rehabilitating underground infrastructure with minimal disruption to surface traffic, businesses, and residents. Also includes technologies for inspection, leak location, and leak detection with minimal disruption and minimal excavation from the ground surface.

U

Unaided Eye

Visual inspection, without the use of special equipment or enhancement excepting the use of corrective lenses.

V

Vitrified Clay Pipe (VCP)

A pipe made from various clays or combinations thereof which are shaped, dried, and fired to a point where the glass-forming components fuse to form a bond between the crystalline grains.

W

Waterstop

Vertical barriers placed across the bottom of the trench to prevent migration of soil fines due to water movement.

Well Points

Single or multiple pipe which are usually fitted with a screen for the temporary removal of water from the bottom of the trench.

Our Member Companies

Our Member Companies

Our Member Companies