Are there any faster installation processes for fast-track projects?

VCP has shorter section lengths than other materials which could result in less pipe laid in a given shift, especially with inexperienced contractors. This can be more dependent on the depth of the installation and utility obstacles than the installed pipe type and length. Where there are multiple utilities, VCP can sometimes be the faster installation. If a project is fast-tracked to get it placed in service, the immediate acceptance testing of VCP actually makes it the better option.

Soil above the pipe settles less than the outside prism soil. Could it be because of improper compaction?

The adjacent (outside) soil prisms will always settle more than the center prism directly above the pipe when a granular material or soil is used in the side fills. If it is necessary to avoid this settlement, use CLSM or concrete bedding in the side fills of the installed pipe.

Can I use slurry (CLSM) to backfill the trench?

Slurry (CLSM) backfill should never be used unless the pipe is bedded with the same material. Any pipe material bedded with a granular product would see, and have to support, the entire trench load of the slurry (CLSM) backfill.

What is the best way to get updated information on proper installation techniques and bedding classes?

NCPI’s Vitrified Clay Pipe Engineering Manual, ASTM C12, NCPI’s Installation and Inspection Handbook and NCPI’s CCTV Handbook are the best sources of current information on installation techniques and bedding classes. The NCPI publications are available online or through our member companies.

If this is your first time to install VCP or if it’s been a few years, we strongly recommend the Installation & Inspection workshop for your inspectors and contractor’s crew.

What is the maximum allowable offset measurement?

Joint offsets (joint steps) could range from 1/8-inch to as much as ½-inch. This variable depends on the pipe diameter. The larger the pipe the greater the possible joint offset (step at the invert between pipe sections) due to dimensional tolerances for diameter and roundness. Modern VCP joints have been tested and continue to be leak-free well-beyond these ranges.

Why is a narrower trench more desirable for VCP installations?

VCP is a rigid conduit, providing structure within the trench. The load on rigid pipe increases as trench width increases. Bedding and backfill contribute to the final field supporting strength of an installation, but the narrower trench limits the amount of load applied to the pipe by the soil prisms above it. Commonly, a minimum of 12-inches is needed on both sides of the pipe for placement and haunching of a granular bedding material.

How do you know when CLSM has cured enough to be backfilled?

Initial backfill can commence once a 500 psi minimum penetrometer reading is achieved. The Optimal CLSM Mix Design was developed to allow for backfilling as quickly as possible, frequently within the same day.

Is there a CLSM bedding mix for same day backfill?

Initial backfill can commence once a 500 psi minimum penetrometer reading is achieved. The Optimal CLSM Mix Design was developed to allow for backfilling as quickly as possible, frequently within the same day. Download the ASCE paper including the test methods and the resultant optimal mix.

What are the deep installation techniques available for VCP?

NCPI has completed many research projects resulting in methods of installation for VCP in deep applications. Our research, specifically on CLSM (Controlled Low Strength Material) is a solution for structurally supporting open trench VCP in deep installations.

Trenchless installation is also an option for deep burial VCP. Vitrified Clay Jacking Pipe can be installed by either using pilot tube or slurry microtunneling methods.

What educational materials do you have for contractors installing clay pipe?

NCPI recommends a training workshop for any contractors without recent experience installing VCP. These training workshops are provided at no cost. Primary installation resources include: Tips for Installing Vitrified Clay Pipe and Vitrified Clay Pipe Installation & Inspection Handbook

Will Clay Pipe float when bedded with CLSM?

In actual practice in the ditch, NO. Theoretically and mathematically, you would expect it to. When you do the math using a standard buoyancy calculation, the pipe should float. However, in actual practice, the CLSM when placed around the pipe forms an immediate friction between the pipe and CLSM. The theory in support of real-world experience is that friction plus the weight of the pipe prevents the pipe from floating. Tests in the field using two concrete trucks dumping their chutes simultaneously, over the top of the pipe did not cause the pipe to float. That being said, NCPI recommends against placement of CLSM at extremely high discharge rates.

For more information on CLSM: Guidelines for CLSM

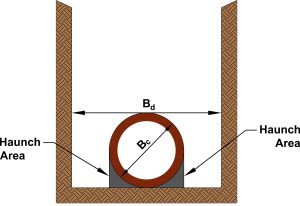

What is haunching?

The haunch is the area bordered by the barrel outside diameter, the vertical tangent from the pipe springline and the horizontal tangent from the bottom of the pipe. Haunching is using a shovel, spade, or other suitable tool to place and compact the bedding material in the haunch to (1) assure the pipe will remain true to line and grade and (2) provide uniform circumferential support to the pipe which is essential for the total load factor to be realized. For more on the Importance of Haunching, download the paper presented at ASCE Pipelines in 2014.

For complete technical information, download our Manual or one of our Handbooks.

*Qualifies for PDH Credits