If you don’t see what you’re looking for, please email us.

Papers & Tech Notes

In over 100-years of research and publication, NCPI has amassed an extensive library. The papers available here include our most referenced materials.

A comparison of vitrified clay pipe (VCP) and polyvinyl chloride (PVC) for use in gravity sanitary sewers, focusing on the long-term environmental impact and cost considerations.

Photo by Hilton Kelley

Vitrified Clay Pipe Thru Steel Casing Procedure

The following procedure for “Installation of Carrier Pipe Within A Steel Casing” is taken from past projects, where this method produced successful installations.

VCP vs. RCP for Gravity Sanitary Sewer

Vitrified Clay Pipe (VCP) and Reinforced Concrete Pipe (RCP) have been utilized for storm and wastewater collection in the United States since the early 1800’s. The first RCP line was installed in Mohawk, NY in 1842 and the first VCP sewer was installed in Washington, DC in 1815. Although RCP and VCP are both rigid conduits with inherent strength built into the pipe, there are some noticeable differences when used in a gravity sanitary sewer system.

Pilot Tube Method of Guided Boring as the Conservative Option

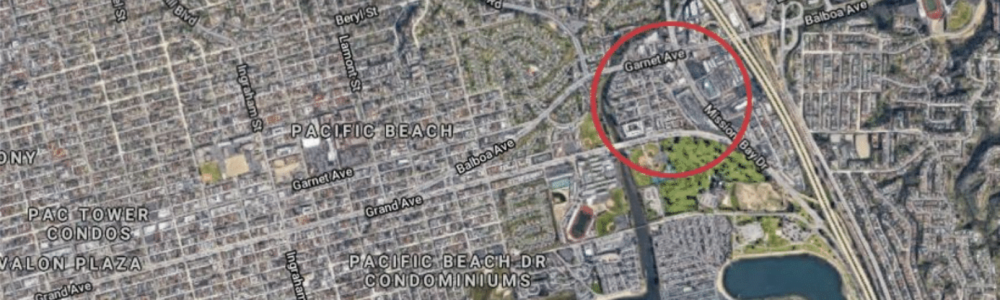

The communities of Mission Bay and Pacific Beach, in San Diego, CA are much like many other ocean-front areas with high tourism, an expectation of uninterrupted services and high-water tables. However, the environmental regulations within the state of California present additional challenges.

Guidelines For Controlled Low Strength Material (CLSM) Mix Design, Placement And Testing For Use As A Bedding Material For Vitrified Clay Pipe

Sanitary Pipeline Pilot Project After 42-Years Of Service In Lima Ohio

2014 Updates To ASTM C12 Final Paper ASCE Pipelines 2015

The Evolution of Jointing Vitrified Clay Pipe

Advances made in the jointing of vitrified clay pipe during the last half century, illustrate the concern of the clay pipe industry to provide top quality jointing methods. Prior to this, the lack of standards for joint integrity meant testing for infiltration and Exfiltration was seldom implemented.

Tech Notes

Tech Note 4: An Economic Approach

Tech Note 5: Infiltration and Inflow (I/I) Studies

Tech Note 6: Deflection

Tech Note 7: VCP and PVC (a comparison)

Tech Note 8: VCP – The Choice for Difficult Conditions

Tech Note 9: VCP – A Pipeline of Progress

Tech Note 10: The Decision is Yours (Lifecycle vs. Installed Cost)

Tech Note 11: Sand as a Bedding Material

Tech Note 12: Curvilinear Sewers

Tech Note 13: CLSM as a Bedding Material

Tech Note 15: A Bell or Coupling Holes and Shovel Slicing

Tech Note 17: Abrasion Resistance

Tech Note 21: VCP Joints

Tech Note 22: Microtunneling with VCP

Tech Note 24: Surcharge Fills

Tech Note 25: NYC Bedding Research

Tech Note 26: VCP Performance in Seismic Events

More Technical Papers

Pilot Tube Microtunneling Chosen in Omaha Nebraska for 585’, Single Drive with Depths Reaching 50’ to Preserve Sensitive Garden Area

by David Gill, Chris Koenig, Chris Cain, Kenton Moore and Tim Papstein – 04/04/2014

Omaha, NE, stretching along the Missouri River for 7 miles, is currently under a consent order with the Nebraska Department of Environmental Quality to improve the water quality in the Missouri River. The estimated construction cost of the program, including sewer separation is $1.7 billion dollars. One project defined by the program was a sewer separation project, which took place in a very sensitive setting, Omaha’s Lauritzen Gardens.

Importance of Haunching

by Jeff Boschert, P.E., MASCE and Amster Howard, MASCE – 01/03/2014

Presented at ASCE Pipelines, 2014 – Testing on bedding practices that don’t include haunching reveal voids and call the assumption of uniform haunch support into question.

CLSM as a Pipe Bedding

by Jeff Boschert, P.E. and John Butler – 01/08/2013

Presented at ASCE Pipelines, 2013 – CLSM as a structural bedding material for VCP. Optimal mixes, methodologies and resultant safety factors are discussed.

Optimal CLSM Mix Design – As Developed by Means of Small Batch Testing

by NCPI – 01/06/2013

These tests were conducted to define the optimal mix for Controlled Low-Strength Material (CLSM) used in gravity sewer applications with vitrified clay pipe. Varying percentages of 3/8-inch coarse aggregate, accelerator and entrained air were tested.

Consideration for Flotation when CLSM is Used as a Bedding Material

by NCPI – 01/01/2013

No field installations using CLSM have resulted in flotation of clay pipe. CLSM is being successfully used as a bedding material for vitrified clay pipe. It simplifies the installation of pipe, reduces labor and inspection costs, allows for early backfill, is easy to place, and provides a 2.8 Load Factor.

A Short Course in Pilot Tube Microtunneling

by David Gill – 01/01/2010

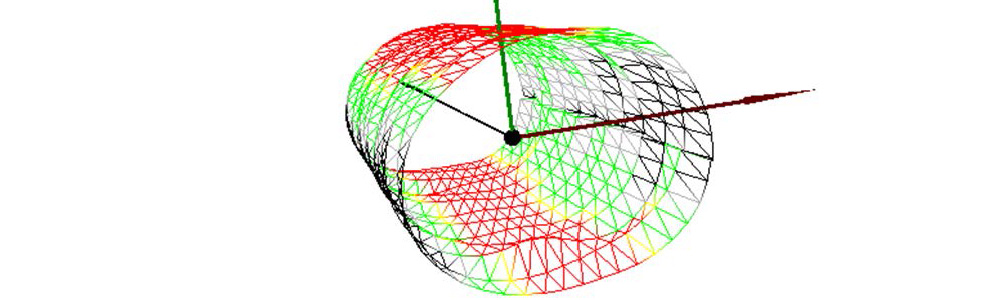

PTMT is generally used for new installation of small diameter gravity flow pipelines. These machines can operate out of a minimal diameter shaft and provide pinpoint accuracy through the use of a LED target viewed down the center of the pilot tubes with a theodolite and LCD monitor. The Pilot Tube Microtunneling (PTMT) method of pipeline installation can be used with pie outside diameters ranging from 4 to 48 inches. PTMT is a trenchless installation method for pipelines with grade and alignment precision to within 1/4 inch per 500 LF throughout the entire drive length. Due to this line and grade accuracy, this system can install product pipe by direct jacking without the use of casing. This method involves a three-step process starting with launch and reception pits strategically located to minimize surface disruption.

Our Member Companies

Our Member Companies

Our Member Companies